Quick question about that sweater or blanket you're clinging to this long winter. Was it "Made in the USA?" And if it's wool, any idea where the yarn came from?

Most wool apparel is manufactured with fine merino wool, which comes from Australian sheep. And global wool production is dominated by that country, as well as New Zealand and China. America ranks 11th in the manufacturing of wool, according to industry data. It's amid this backdrop that the work of Minnesotan entrepreneur Stephenie Anderson stands out.

Related: 9 Startups Bringing 'Made in USA' Back to Clothing

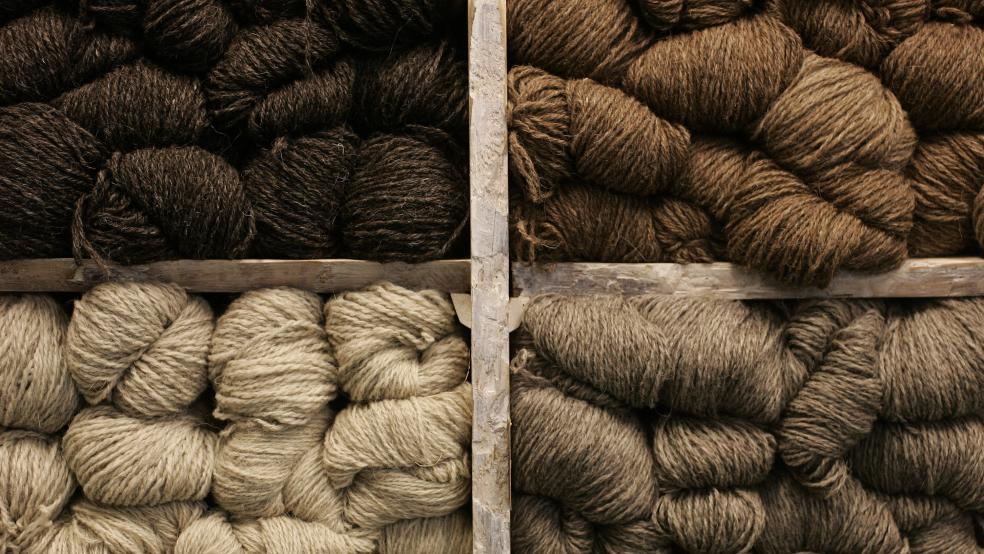

In the dead of winter in December, Anderson and her eight-employee business flipped the switch on a brand new wool mill that produces bundles of finished wool yarn—something the region hasn't seen in some 50 years. Her business customers, stretching to the East Coast, turn her yarn into blankets, garments and upholstery—all "Made in the USA."

Clearly the American wool supply chain—from sheep to yarn to final product—is leaner than decades past. Most wool from American sheep can be scratchy, not the soft stuff from Australian animals. But the business environment for U.S. wool is shifting, if ever so slightly on a small scale.

Domestic textile innovations allow for the creation of softer fibers made with tougher yarn. More small- to mid-sized businesses are realizing it's no longer cost effective to outsource materials and business to other countries, including China. So through a word-of-mouth network of yarn producers, spinners and dyers, scrappy entrepreneurs are keeping the "Made in USA" wool tradition alive, and in some cases sparking growth.

'Crazy' innovative

Anderon's Northern Woolen Mills is located in a remote Minnesota town of about 1,500, which makes the new mill even more remarkable. Fosston is far from Chicago and other manufacturing hubs President Barack Obama has been showcasing.

Related: Five Myths About U.S. Manufacturing

Anderson, a life-long knitter, realized the region including local sheep farmers needed a mill. She sold one of her homes, and scraped together roughly $755,000 to cover the mill's cost. Mill blueprint in hand, her small team bought equipment, some weighing three tons—operating instructions not included. The new mill team had to rely on retired mill machinery mechanics and YouTube videos—in Spanish—to learn how to operate some of the machinery. "We don't speak Spanish here. We just watched it until we figured it out," Anderson recalled. "I think I might have been crazy."

Her mill produces 100 pounds of finished yarn a day and fills a processing need by regional sheep ranchers. The last time Fosston had a running mill was during the 1920s. Another mill in Bemidji, about 45 miles away, stopped making yarn in the '60s, though they're still in business. So without Anderson's mill, sheep ranchers previously had to find space on a semi load of raw wool traveling to, say, North Carolina. Sometimes the only option was to ship wool to Canada. But crossing borders means getting slapped with tariffs. Eliminating long-distance shipping saves time, money and reduces the carbon footprint. "Local sheep shearers are coming out of the woodwork," Anderson said.

How Many Wool Suits Do You Own?

Most consumers think Australia when it comes to sheep and wool apparel. But Minnesota also has a wool tradition. The iconic, checkered Buffalo coats originated in Minnesota. Minneapolis is known for its heritage of making wool blankets.

But the wool industry collectively took a hit beginning in the 1980s, when domestic mills started to shutter. Lower-cost, overseas producers began to emerge.

Related: Wal-Mart, Bangladesh and the Real Cost of Cheap Clothes

Consumer tastes and office dress codes changed too, as men bought fewer suits, said David Trumbull, a consultant and expert in textiles and U.S. manufacturing. Warmer winters and better-insulated homes also meant lower demand for wool blankets and throws. By the mid 1990s to 2000, U.S. mill consumption of raw wool collapsed by 47 percent to 74.8 million pounds, according to a 2001 U.S. International Trade Commission report.

'Huge Risk'

Beyond a handful of larger, commercial operations, most remaining U.S. wool mills are small- to mid-sized businesses, which makes tracking their numbers very difficult. But among them is new mill operator Anderson. She set out only to produce yarn, but has expanded into fiber processing. And beyond sheep, the mill produces yarn from bison hairs, some of which can be softer than cashmere.

Her textile innovations are part of a mini-manufacturing hub that's taking shape in Fosston. The mill's industrial park includes a business that dehydrates honey and molasses for dry cereals. Another venture dehydrates vegetables that go into dog food and canned soup. "It's this very niche agricultural, industrial park," Anderson explained.

Reflecting back on her decision to open the mill, "It was a huge risk." A risk so far that's creating a following Anderson hopes will lead to a profit. Her customers include local Bemidji Wollen Mills in Minnesota to farm2fashion, a small apparel maker devoted to turning American wool into sweaters, throws, blankets and other accessories. Founder of farm2fashion Laurie Perrone, based in Cornwall, N.Y., said she wanted to support independent American farmers and crafts people. Her raw materials also come from Pennsylvania—not abroad.

Related: Retailers Battle for Every Consumer Dollar

By sourcing locally, Perrone said she's able to design and react immediately to customer and inventory needs. "We're really answering the speed-to-market problem," she said.

So whether it's to save time and money or a desire for natural fibers, consumer interest for wool is rising. Just ask Anderson of Northern Woolen Mills. "A guy from Switzerland came last week, just to see the mill," she said. Mind you, the town is small. The local hospital, a large employer, has fewer than 20 beds. "It's hard to find stuff that's made in America," Anderson said. "Now I'm looking at every single label."

This article originally appeared in CNBC.

Read more at CNBC:

Made in USA Fuels New Manufacturing Hubs in Apparel

Welcome Home: Made in USA on the Rise

How Investors Can Play the Energy Boom